Productbeschrijving:

Deeltjes voor gietgiet spelen een cruciale rol in de moderne productie en bieden hoge precisie, duurzaamheid en veelzijdigheid in verschillende industriële toepassingen.Onze gietproducten zijn ontworpen om aan de strengste kwaliteitsnormen te voldoen.Met een sterke toewijding aan uitmuntendheid is ons productieproces gecertificeerd volgens ISO/TS16949:2009, die garandeert dat elk geproduceerd zinklegeringsgietonderdeel voldoet aan strenge kwaliteitseisen voor de automobielindustrie en de industrie.Deze certificering weerspiegelt onze toewijding aan het leveren van producten die voldoen aan en overtreffen de verwachtingen van de klant.

Een van de belangrijkste kenmerken van onze gietstukken is het gebruik van multi-holte malen.de efficiëntie aanzienlijk verbeteren en de doorlooptijden verkortenDeze methode verhoogt niet alleen de productiviteit, maar zorgt ook voor uniformiteit en consistentie in alle onderdelen, wat essentieel is voor toepassingen die hoge precisie vereisen.Of u nu een kleine partij of massaproductie nodig heeft, kan ons multi-holte gietproces op maat worden gemaakt om aan uw specifieke behoeften te voldoen, waardoor kosteneffectieve oplossingen worden geboden zonder afbreuk te doen aan de kwaliteit.

De oppervlakte is een ander belangrijk aspect van onze gietstukken.We begrijpen dat verschillende toepassingen verschillende oppervlaktebehandelingen vereisen om de gewenste esthetische en functionele eigenschappen te bereikenDaarom zijn onze oppervlakte afwerkingsprocessen flexibel en kunnen worden aangepast volgens de vraag van de klant.Onze geavanceerde oppervlaktebehandelingsmogelijkheden zorgen ervoor dat elk zinklegeringsgietonderdeel niet alleen goed presteert, maar ook voldoet aan de visuele en tactiele normen die door uw industrie worden vereist..

De kwaliteitscontrole staat centraal in ons productieproces. Onze faciliteiten werken volgens het kwaliteitsmanagementsysteem ISO 9001:2015, waardoor systematische controle over elke fase van de productie wordt gewaarborgd.Van de grondstofinspectie tot de eindproductproeven, wordt elk gietproduct onderworpen aan strenge kwaliteitscontroles om de dimensie-nauwkeurigheid, sterkte en duurzaamheid te garanderen.Onze kwaliteitscontrole protocollen minimaliseren gebreken en ervoor zorgen dat de kamer die gieten componenten voldoen aan de hoogste normen, waardoor onze cliënten gemoedsrust hebben.

Onze gietonderdelen vinden een uitgebreide toepassing in industriële apparatuur, waar precisie en duurzaamheid van het allergrootste belang zijn.en consumentenproducten profiteren allemaal van de sterkte en veelzijdigheid van zinklegerings gietonderdelenDe in ons productieproces gebruikte techniek van kamerstijgingen zorgt voor een optimale materiaalstroom en -verharding, wat resulteert in onderdelen met uitstekende mechanische eigenschappen en complexe geometrieën.Dit maakt onze producten ideaal voor veeleisende industriële omgevingen waar prestaties en levensduur van cruciaal belang zijn.

Kortom, onze gietproducten bieden een combinatie van geavanceerde productietechnologie, strenge kwaliteitsborging en aanpasbare oppervlakteafwerking om aan diverse industriële behoeften te voldoen.Met ISO/TS16949De certificering van 2009 ondersteunt onze zink legering gietstukken, multi-holte productie efficiëntie, en ISO 9001:2015 kwaliteitscontrole normen,we bieden betrouwbare en kwalitatief hoogwaardige oplossingen voor industriële apparatuur toepassingenOf u nu complexe gietcomponenten of standaard gietonderdelen nodig heeft,Onze expertise en toewijding zorgen ervoor dat u producten ontvangt die uw operationele efficiëntie en productkwaliteit verbeteren..

Kenmerken:

- Naam van het product: gietstukken

- Proces: Aluminium gieten + bewerking

- Microbewerking: Ja, dat is het

- Toepassing: industriële apparatuur

- Tipe dienst: op maat gemaakt & OEM

- Inclusief delen voor gietgiet van zinklegeringen

- Gespecialiseerd in onderdelen voor het gieten van aluminium

- High precision aluminium gietstukken beschikbaar

Technische parameters:

| Producten |

Deeltjes voor gietgiet |

| OEM-producten |

Beschikbaar |

| Verwerking |

Aluminium gietwerk |

| Proces |

Aluminiumgietwerk + bewerking |

| Toegepaste |

Industriële apparatuur |

| Hoogte |

Multi-holte |

| Sleutelwoord |

Deeltjes voor gietgiet |

| Microbewerking |

Ja, dat is het. |

| Soort dienst |

Tailor Made & OEM |

| Kwaliteitscontrole |

ISO 9001:2015 |

Toepassingen:

De Race Die Casting Parts, met trots gemaakt in China, zijn ontworpen om aan de hoogste kwaliteits- en precisienormen te voldoen, waardoor ze ideaal zijn voor een breed scala aan toepassingen.Als toonaangevende fabrikant van gietstukken, Race is gespecialiseerd in legering aluminium gietgieten, waardoor duurzame, lichtgewicht en corrosiebestendige componenten die essentieel zijn in veel industrieën.

Een van de belangrijkste toepassingsscenario's voor Race Die Casting Parts is in de automobielindustrie.overbrengingsbehuizingenDankzij de gebruikte multi-holte vormtechnologie kan Race complexe en grootschalige onderdelen efficiënt produceren.catering voor zowel OEM- als op maat gemaakte servicevereisten.

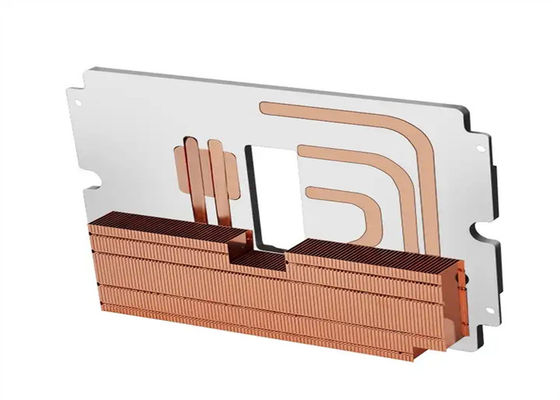

Naast automotive toepassingen zijn Race Die Casting Parts ook geschikt voor industriële machines, elektronica en consumptiegoederen.Het gietproces van legering aluminium levert uitstekende warmtegeleidbaarheid en mechanische sterkte, waardoor deze onderdelen een uitstekende keuze zijn voor warmtezuigers, behuizingen en structurele dragers in verschillende apparatuur.

Race zorgt voor strikte kwaliteitscontrole in overeenstemming met ISO 9001:2015 en de kwaliteitsverzekeringsnormen ISO/TS16949:2009Bovendien zijn de producten gecertificeerd volgens ISO9001, ISO14001 en TS16949,een weerspiegeling van de toewijding van het merk aan milieubewustzijn en superieure productiepraktijken.

Klanten profiteren van flexibele bestelopties met een laag MOQ en onderhandelbare prijzen.Race Die Casting Parts een toegankelijke oplossing voor zowel kleinschalige prototyping als grootschalige productieDe verpakkingen worden op maat gemaakt volgens de eisen van de klant om een veilige levering te garanderen, met een typische levertijd van 20 dagen.

De betalingsvoorwaarden zijn zo ontworpen dat het voor de klant gemakkelijk is, waarbij een voorschot van 30% TT met het saldo voorafgaand aan de verzending vereist is.De oppervlakteafwerking van de gietstukken kan worden aangepast aan de specifieke esthetische of functionele behoeften van de klant, waardoor de toepasbaarheid ervan in verschillende sectoren verder wordt verbeterd.

Kortom, Race Die Casting Parts zijn veelzijdige en betrouwbare componenten die geschikt zijn voor automotive, industriële en consumentenproducten toepassingen.in combinatie met strenge kwaliteitscontrole en aanpasbare diensten, maken ze een voorkeur keuze voor fabrikanten die op zoek zijn naar hoogwaardige auto-onderdelen en andere precisiecomponenten.

Uw bericht moet tussen de 20-3.000 tekens bevatten!

Uw bericht moet tussen de 20-3.000 tekens bevatten! Controleer uw e-mail!

Controleer uw e-mail!  Uw bericht moet tussen de 20-3.000 tekens bevatten!

Uw bericht moet tussen de 20-3.000 tekens bevatten! Controleer uw e-mail!

Controleer uw e-mail!